|

Rivergreen Developments

new

rammed earth building is

unusual for a

developer of this type,

they buy land, develop it using their own workforce, no

subcontractors, and then lease rather than sell. For us this was an

exciting challenge, the first UK rammed earth building by

non-specialist architects, engineers, surveyors and contractors.

The project began with

soil selection, the site itself yielded 100% sand, this needed the

addition of clay and gravel. Testing was handled through academic

specialists at Bath University, lead by Professor Peter Walker. More

images of the

rammed earth component of the build.

Once the mix was tested

and agreed we provided off site training to the Rivergreen in house

team. Because they all worked together and knew each others skills the

transfer of information on soil mixing, handling, placing and ramming,

as well as the assembly and stripping of the formwork was highly

effective. Often contractors subcontract different parts of the same

job to different companies or individuals which leads to information

delivered in training getting lost, misunderstood or ignored. In this

case the team was well motivated and secure in their positions.

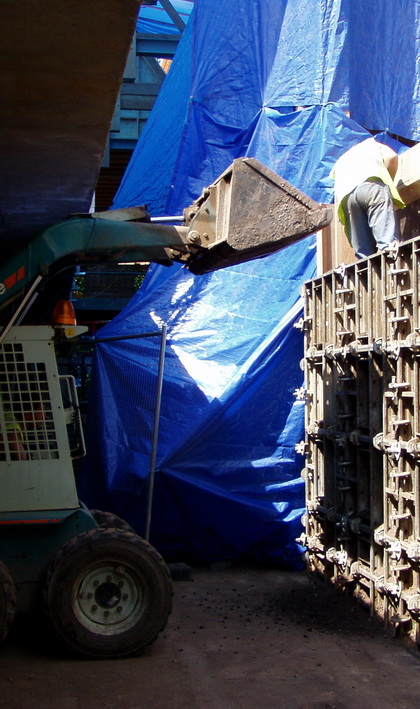

The material mixing was

done separately from the building of the wall. This allowed them to

choose a time to mix outside in fine weather, place the mix in bulk

bags and store them on site. Bulk

|

|

|

|

bags allow storage in a

smaller area than in a heap, and is easier to cover and protect from

rain. This means the initial dig for foundations does not get in the

way of the job but secures the materials for when they are needed.

In this case the shell of

main building is timber and the frame and cladding were largely in

place when the rammed earth atrium wall was finally begun. Whatever

the weather outside the material was ready to use and unaffected by

climate.

We were building a large

job at the other end of the country when Aykley Heads started ramming.

With some telephone consultancy a few minor issues were quickly dealt

with and the contract was completed very successfully 'in house'

Speaking to Peter Candler the client recently he

made a couple of very interesting points about the building. Initially

it was 80% leased to a large public

sector organisation but at the end of the 7 year

lease with the economic situation being bad they gave up the lease.

Faced with an almost empty building in difficult times didn't look

good. But in fact the building was fully leased within six months. His

point was that building high spec and with materials like timber and

earth is a positive benefit when times are hard. Of all the empty

office space in the north east England it is the special buildings

which can sell themselves. So building with earth becomes an economic

virtue and necessity rather than a risk... |

|

|

|

|